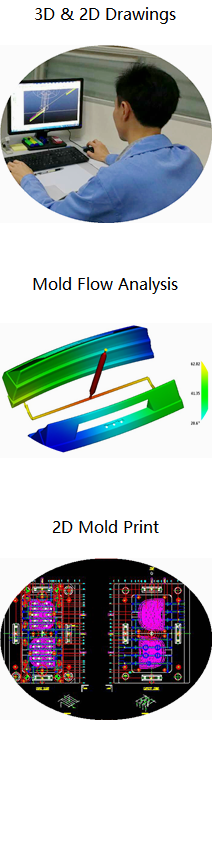

In-house Product Design, Prototyping and Mold Design

Haida established an engineering and design department which is ready to provide value-added professional engineering and design services to both local customers and overseas customers.

Serving a wide range of industries including medical, aerospace, consumer products, and electronics, our experienced designers and engineers work with the up-to-date software to ensure our reputation as a reliable and efficient one-stop supplier.

Our engineering services start from reverse engineering, through product design, design verification, mold design, etc. Thus, whether you have a completely new concept or you would like to improve existing design, we can offer perfect engineering and design services you need.

The software we use include Pro_E, Solidworks, UG, etc.

Reverse Engineering

Haida offers reverse engineering services to obtain the geometries and surface characteristics of parts.

Our engineers take advantage of the most precise metrology equipment available to scan offered samples and create 3D models to capture the objects’ original designs with excellent precision.3D scanned point cloud data will be converted to 3D models to provide customers with an analysis of their structure, function, etc.

For nearly 20 years, we are always servicing our customers with low-cost and short-lead time solutions.

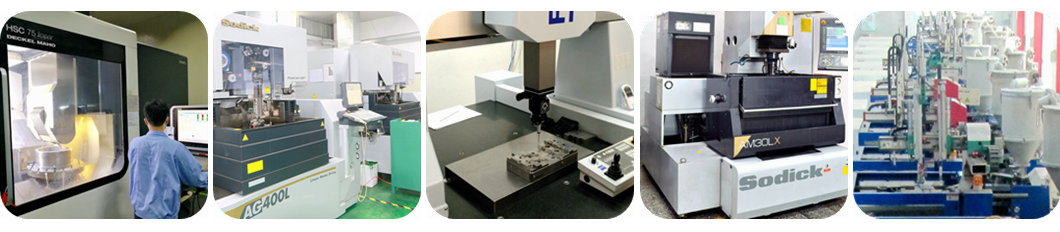

Machined Prototypes and Rapid Prototypes

We are specialized in both rapid prototypes and machined prototypes.

Our customer-oriented team of engineers are always ready to work with you to make your product ideas a reality. For nearly 20 years, our customers are always benefiting from the prototypes we provide.

Thanks to the existence of prototypes, our customer can see physical models of their products, demonstrate the appearance, dimensions and function of the products to their customer and save time and money by identifying and fixing design flaws before formal production.

Moldflow Analysis

Moldflow analysis can study process before manufacturing molds. It helps analyze material characteristics and behaviors in areas like melt flow, pressure drop, fill time, increasing accuracy, etc.

With up-to-date software, our experienced engineers can identify problems and provide solutions in advance and have helped customers achieve countless improvements while creating innovations.

Mold Design

For nearly 20 years, we are providing perfect mold designs to our customers for 2-plate, 3-plate mold, hot runner molds and other molds with complicated mechanism.